Babcock & Wilcox has been awarded a contract to conduct front-end engineering and design (FEED) for Varme Energy Inc.’s planned waste-to-energy with carbon capture and sequestration project in Alberta, Canada.

As part of the contract, B&W will conduct engineering and design for the plant’s waste-fired boiler, emissions control technologies and post-combustion carbon capture system, according to a news release.

“This initial engineering contract is an important first step in what we anticipate will be an exciting, large-scale municipal waste-to-energy with carbon capture and sequestration project,” said B&W Chief Operating Officer Jimmy Morgan. “We’re pleased to partner with Varme Energy to help turn waste into a clean energy source with reduced greenhouse gas emissions.”

“B&W is committed to providing our customers around the world with advanced solutions to generate energy from waste while reducing reliance on landfills and safeguarding the environment,” Morgan added.

“With the signing of the front-end engineering and design contract, Varme Energy is pleased to partner with Babcock & Wilcox to advance the development of the first waste-to-energy with carbon capture and sequestration facility in Canada,” said Varme Energy Chief Operating Officer Wayne Carey. “Leveraging B&W’s global experience in delivering safe, proven and environmentally sound waste-to-energy facilities is our first step in reducing waste destined for landfills and providing clean, reliable electricity.”

The proposed facility would be constructed northeast of Edmonton and would be capable of processing up to 200,000 tons of waste per year.

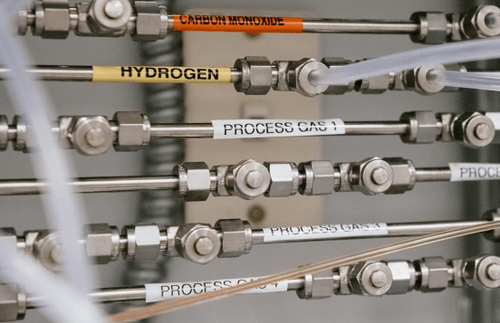

Following completion of the FEED contract, B&W’s anticipated scope for the proposed project would include the design, supply and construction of the plant’s combustion grate, boiler and economizer, as well as the design and supply of the air quality control system (AQCS) for particulates, nitrogen oxide and sulfur oxides, and a carbon capture absorber and sorbent regeneration system.