OCOchem has completed its Phase II project with United States Army to develop and test its 15,000cm2 formate electrolyzer cell.

The company scaled up from 10 to 15,000 cm2 over four steps in three years to achieve an industrial scale form factor. As a result of this new benchmark, OCOchem’s CO2 electrolyzer is 650% larger than other platforms, its final industrial scale cell size and is now scaling out into multi-cell stacks in a larger scale pilot plant, according to a news release.

ReSource previously interviewed OCOchem CEO Todd Brix, who said that the firm would seek to raise money later this year or early in 2025, and that its first commercial plant in Richland, Washington will cost “multiple tens of millions of dollars.”

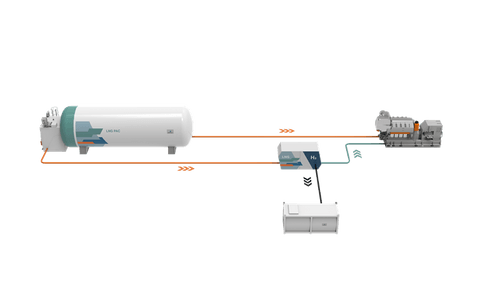

OCOchem specializes in making an organic platform molecule known as hydrogen formate through CO2 electrolysis, leveraging clean electricity and advanced engineering technologies, instead of sunlight and plant biology, to transform carbon dioxide and water into valuable carbon-based molecules. Formate serves as a crucial precursor chemical, providing both carbon and hydrogen together in a single liquid molecule instrumental in synthesizing a diverse array of derivative materials, chemicals, and fuels. It is the liquid form of energized CO2 ready for use. OCOchem’s process to make formate is known as “electro-formation” and is designed for high (104%) carbon-to-product efficiency, high (85%) energy efficiency, room temperature and pressure operation, and lack of waste by-products.

The CO2 electrolyzer produces a safer and sustainable liquid platform chemical, hydrogen formate, which can be made at a lower cost than existing fossil-based pathways as it uses CO2, water, and clean electricity as its only raw materials. Formate is also used as a platform molecule to make many other molecules, which constitute more than 20% of the $3.5 trillion/year global chemical market.