Conestoga Energy and SAFFiRE Renewables announced today their agreement for Conestoga to host SAFFiRE’s cellulosic ethanol pilot plant at Conestoga’s Arkalon Energy ethanol facility in Liberal, Kansas, according to a news release.

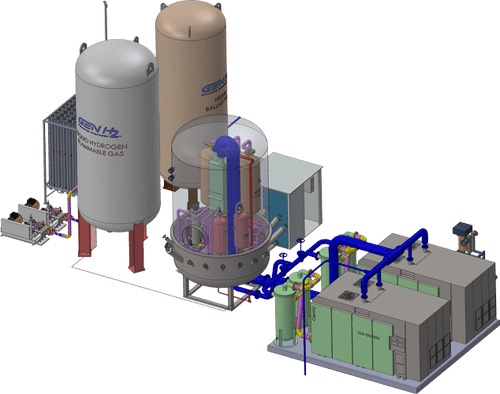

The SAFFiRE pilot project aims to validate and demonstrate the commercialization of SAFFiRE’s corn-stover-to-ethanol technology in a fully integrated pilot facility that processes 10 tons of corn stover per day. Both Conestoga and SAFFiRE are focused on producing ultra-low carbon intensity (CI) ethanol for use in renewable fuels, making this a synergistic relationship.

The cellulosic ethanol from the SAFFiRE pilot project and potential future commercial facilities is planned to be upgraded to ultra-low CI sustainable aviation fuel (SAF) in support of the aviation industry’s decarbonization efforts. SAF is fuel produced from non-fossil fuel sources that can result in lower greenhouse gas (GHG) emissions than conventional jet fuel on a lifecycle basis. SAF is a drop-in fuel when blended with conventional jet fuel and is crucial to decarbonizing aviation.

SAF’s lower carbon intensity makes it an important part of reducing aviation GHG emissions, which make up 9%–12% of U.S. transportation GHG emissions, according to the U.S. Environmental Protection Agency.

“Conestoga is excited to work with SAFFiRE Renewables on this transformative opportunity. This agreement ties in well with Conestoga’s rich history of providing carbon reducing and net zero solutions in the bioethanol space,” said Tom Willis, CEO of Conestoga Energy. “In order to reach stated net zero carbon emission goals by 2050, the aviation industry will have to embrace SAF. SAFFiRE cellulosic ethanol technology is planned to produce ethanol that can be upgraded to SAF that can be cost-competitive with traditional fossil-based jet fuel. Conestoga is proud to be a part this next big step for both the Ethanol and Aviation industries.”

“A tremendous amount of engineering and site design work has been completed and we’re confident that this pilot plant will be the first step toward scaling and commercializing the conversion of corn stover to cellulosic ethanol, which SAFFiRE plans to convert to sustainable aviation fuel through the alcohol-to-jet pathway,” said Tom Nealon, CEO of SAFFiRE Renewables. “This is good for the corn growers, it’s good for ethanol producers, and it’s good for the host communities and the aviation industry. Our pilot plant site selection process was rigorous, and Conestoga exceeded all of our requirements and continues to demonstrate that they are an outstanding partner.”.