Rimere, a climate solutions company with proprietary plasma technology, is seeking to raise an additional $15m as part of its ongoing Series A capital raise.

The start-up recently announced an anchor investment of $10m from Clean Energy Fuels Corp, a publicly listed renewable natural gas firm, and is pursuing further investments from strategics and financial players, with an eye on closing the round in 2Q24, CEO Mitchell Pratt said in an interview.

The company is not currently working with a financial advisor on the Series A capital raise, Pratt said. Its legal counsel is Morrison Foerster.

The anchor investment along with additional funds raised will allow Rimere to advance development and field testing of its two principal products, the Reformer and the Mitigator.

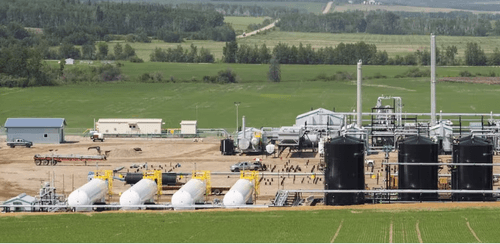

The Mitigator is a plasma thermal oxidizer that reduces the greenhouse gas potency of small-scale fugitive methane emissions, while the Reformer transforms natural gas into clean hydrogen and usable graphene without creating any CO2 emissions.

The products are meant to work in tandem to decarbonize natural gas infrastructure and deliver cleaner gas to end users in transportation, power generation, and industry.

“We believe that, overall, what the technology does is revalue natural gas reserves and the long-term viability of natural gas for global future energy,” Pratt said.

Commercial strategy

Rimere will develop a commercial strategy throughout the course of this year for the Mitigator, and plans to deploy the product in the beginning of next year.

“We have quite a bit of interest for this as a solution because of the low cost of the product and the terrific results,” Pratt said, noting that the Mitigator removes CO2 for under $5 per metric ton.

In contrast, the Inflation Reduction Act passed in 2022 introduced the Methane Emissions Reduction Program, a charge on methane emitted by oil and gas companies that report emissions under the Clean Air Act. The charge starts at $900 per metric ton of methane for calendar year 2024, increasing to $1,500 for 2026 and beyond.

To be sure, the Mitigator, as a thermal oxidizer, transforms methane, which is a much more potent greenhouse gas, into hydrogen, water, and CO2 for a net reduction of the global warming impact of 200 metric tons a year of CO2.

The Reformer, a container-style unit, is being scaled up to produce 50 kg per day of hydrogen from natural gas along with 150 kg of graphene, a marketable nano carbon where the CO2 is captured. Graphene is used in batteries, composites, medical devices, and concrete to reduce greenhouse gas emissions, among other applications.

Rimere plans to increase the scale of the Reformer to between 400 – 600 kg per day and raise additional funds next year, Pratt said. The amount of funds needed for that is not yet known, he said.

Pratt envisions an application for hydrogen blending using the two products.

“We see it as a way to decentralize hydrogen production, taking advantage of a cleaner natural gas infrastructure, because we’ve applied the Mitigator to cleaning up those fugitive methane emissions that are occurring in the normal operations of equipment,” Pratt said.

For example, Rimere can tap into a natural gas pipeline, take a slipstream of gas, extract the valuable graphene, and then re-inject hydrogen and natural gas back into the pipeline.

Additionally, the blending application can be positioned at an end-use customer’s facility, allowing the Reformer to start blending hydrogen into the gas stream, going into boilers and burners and reducing the CO2 emissions more effectively and immediately, Pratt said.

$1 per kg

Taking the average cost of delivered natural gas and power to industrial users, the company can already produce hydrogen at $1 per kilogram, Pratt said.

For every four kilograms of end-use product – one being hydrogen, the other three graphene – the energy cost allows hydrogen to be produced at or below $1 per kg.

“The last 12 months of running is less than a dollar,” he said, emphasizing that the graphene production is not subsidizing the hydrogen.

“Although the value of graphene could make hydrogen a throwaway fuel.”