The owners of Vopak Moda Houston, a Gulf Coast hydrogen and ammonia terminaling asset, have hired an investment bank to run a sale process, according to two sources familiar with the matter.

Intrepid Investment Bankers has been retained to run the process, the sources said.

Vopak Moda and Intrepid did not respond to requests for comment.

Formed in 2016, Vopak Moda Houston is a 50/50 joint venture between Royal Vopak and Moda Midstream. Moda Midstream is a portfolio company of EnCap Flatrock Midstream, which did not respond to a request for comment.

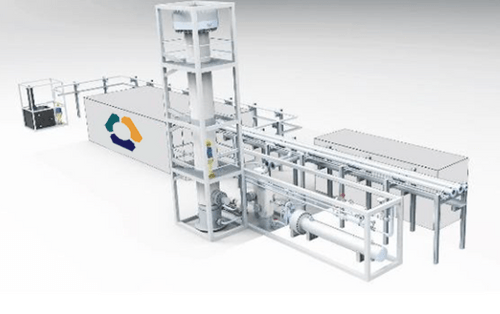

In 2021 the JV commissioned its deepwater dock at the Port of Houston. It has constructed storage and terminal infrastructure for industrial gas product lines, with the stated intention of becoming a premier hydrogen and low-carbon ammonia terminaling hub in the Gulf Coast.